Triple Layer Roll Forming Machine

The Triple Layer Roll Forming Machine, also called Three Layers Machine, or Multi- Layers Steel Forming Machine, shares same uncoiler, machine base, main motor, electrical cabinet, etc and can produce three different profiles in one machine.

Usually the three layers machines is used to make steel roof sheet, corrugated sheet, wall panel, etc.When one layer works, the other two layers will not running, so it can save the power.

Main Components of Triple Layers Machine

Hydraulic Uncoiler

1. Max weight: 6T

2. With or without coil car

Main Roll Forming Machine

1. It adopts three layers structure; each layer is separated designed to produce one type of profile sheet.

2. Roll stations: 16/20/28 stations for each layer.

3. Main motor power: 7.5KW, one set, it adopts cycloid cone pulley reducer, chain transmission.

4. Material of the roller: 45# steel, chromeplate

5. The roller processed by CNC machine with finish machining. The surface adopt finished polishing, the roughness is 0.05mm

6. Material of the main shaft: 45# steel forged steel with heat treatment

Cutter of Three Layers Roll Forming Machine

1. Adopt post cutting, automatic cut to length.

2. Material of cutter: GCr12, quenching, the hardness is HRC58-62

3. Cutting accuracy: 10m ±2mm in length

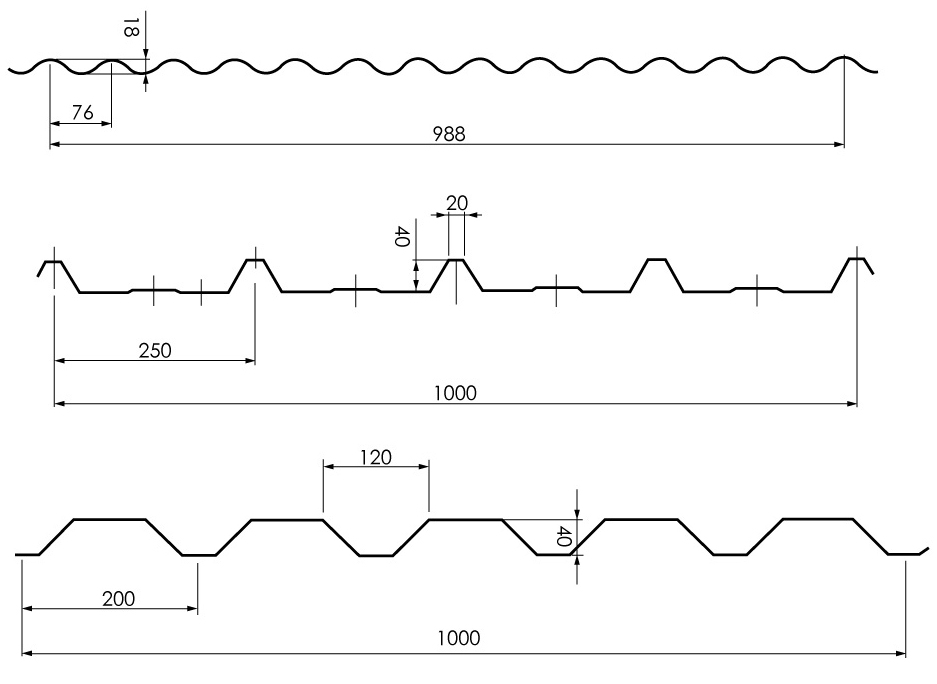

Typical Profile Drawing of Three Layers Roll Forming Machine

Specification

|

Item |

Parameters |

|

Coil thickness (mm) |

0.4-0.8 |

|

Max speed (m/min) |

0-12m/ min |

|

Profile type |

Customized |

|

Roll stand |

18/ 20/ 22 |

|

Main power (Kw) |

7.5 |

|

Main shaft (mm) |

Ø70 |

|

Cutter material |

Cr12 |

|

Cutting accuracy |

10±2mm |

|

Hydraulic station power (Kw) |

5.5 |

|

Control system |

PLC |