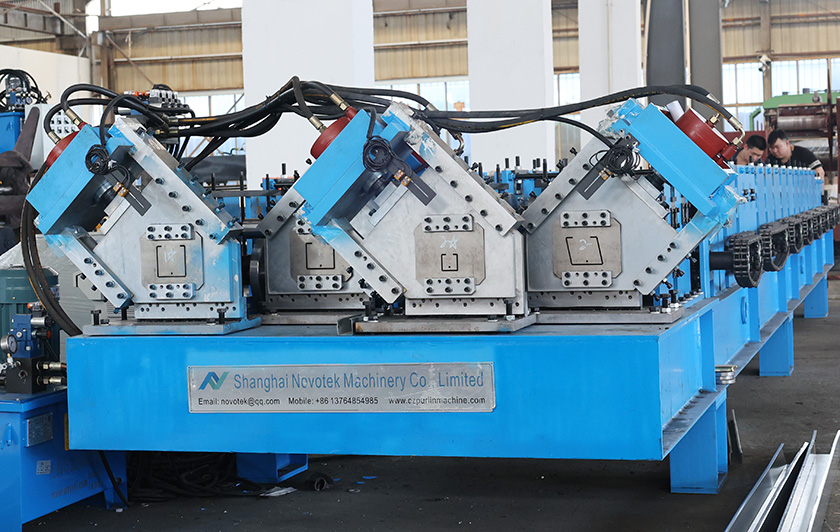

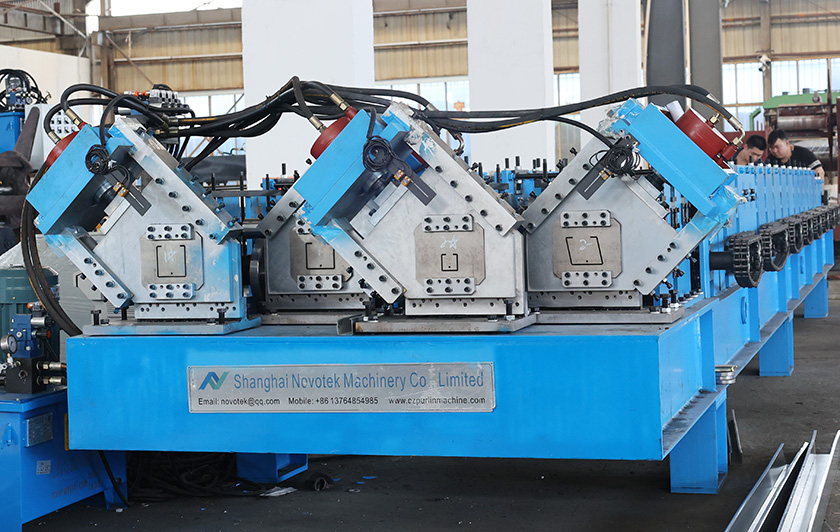

Machine Introduction:

The multi-profile purlin roll forming machine, also called multi lanes purlin roll former, is used to produce different C Z U purlins in one machine. Different with normal purlin roll forming machine which can produce only one product, this roll former is much more effective and saves the factory space.

The 4 lanes purlin roll forming machine including:

1) Hydraulic uncoiler for 4 lanes steel coils

2) 4 lanes guiding rail

3) 4 lanes feeding table

4) Main roll forming machine for 4 different C Z U purlins

5) Hydraulic cutter separately for 4 different products

6) Roll former electrical cabinet

7) Run-out table

Machine detailed specification:

1. General Description:

1.1. Speed: 0-20min

1.2. Voltage: 480V AC, 3 phase, 60 Hz

2. Raw Material:

2.1. Type: galvanized sheet, Gr60

2.2. Thickness: 1.3-1.9mm

3. Uncoiler:

3.1. Expanding type: Hydraulic expanding

3.2. Decoil type: Motorized active decoil

3.3. Loading capacity: 5 T

3.4. Control type: Its speed is automatically adjusted to main machine

3.5. Inner diameter: Ø480-625 mm (most common=610mm)

3.6. Max coil height: 1,335 mm

3.7. Arms & clamps = 475mm

3.8. Coil car: Included

4. Guiding Rail

4.1. Used to feed material as straight

4.2. Rail length: 450mm long for each lane, adjustable up to 3mm per side to allow for variable coil width.

5. Feeding Table:

5.1. Including feeding shaft and feeding rollers.

5.2. Rollers are solid shaft with heating treatment, polishing and galvanizing.

6. Main Roll Forming Machine:

6.1. 4 lanes roller stations for 4 different profiles. Only 1 lane can work each time.

6.2. Roll stand: about 15 stations for each lane.

6.3. Main power: 15 Kw, 3-phase asynchronous motor; chain transmission.

6.4. Material of the roller: GCr15, quenching

6.5. The roller processed by CNC machine with finish machining. The surface adopts finished polishing, the roughness is 0.05mm

6.6. Material of the main shaft: 45# forged steel with heat treatment

6.7. The diameter of the main shaft: Φ70 mm

6.8. Material of frame: welding by H shape steel, by using carbon dioxide gas arc welding. The surface used shot blasting treatment.

6.9. Main machine with top mesh cover.

7. Hydraulic Post-Cut:

7.1. Adopts post fixed cut, cutting when machine stops.

7.2. Each lane has its independent cutter, only 1 cutter is working each time.

7.3. The 4 post-cut adopts 4 separately hydraulic valve and shares 1 hydraulic tank. Each cutter could separately work and controlled.

7.4. Cutter type: mold cut; each size requires one blade. Including 4 pieces blade.

7.5. Hydraulic power: 5.5 Kw.

8. Electrical Cabinet:

8.1. Control cabinet: 1 set. With ‘emergency stop’ switch.

8.2. Control handle: 1 set, for jog control during machine testing and production.

8.3. Operation platform: HMI & Button, with English language display.

8.4. Control system: PLC

8.5. Key components: Key components adopt international famous brand.

9. Runout Table:

9.1. Free roller type.