A) Introdução Geral

B) Principais componentes da máquina de conformação de rolos de purlin de alta velocidade

1. Desbobinador Hidráulico com Carro de Bobina

2. Estação de Achatamento

3. Estação de Soco

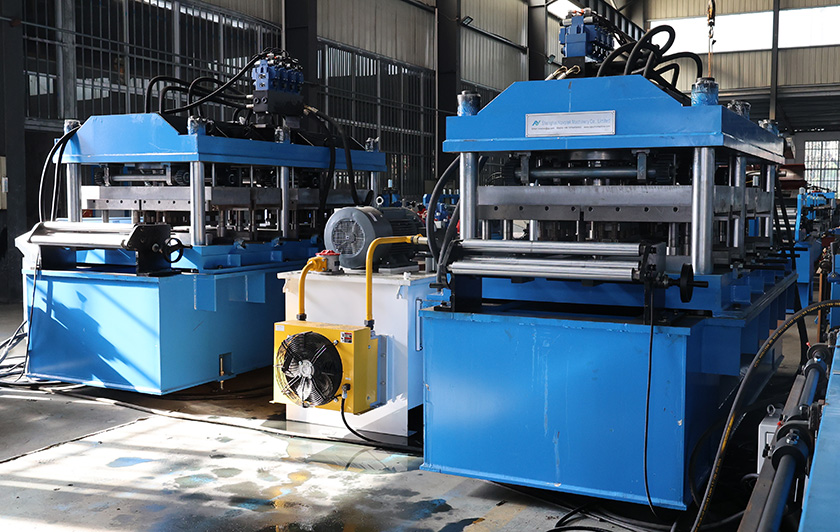

4. Linha principal de conformação de rolos

5. Corte de mosca

6. Sistema de controle e fornecimento de energia

C) Fluxo de layout da máquina de conformação de rolos

D) Descrição detalhada de cada sistema de máquina de conformação de rolos

1. Em geral

2. Matéria-prima

3. Desbobinador Hidráulico com Carro de Bobina

4. Estação de nivelamento

5. Estação de Soco

6. Máquina de conformação de rolos principal

7. Corte de mosca

8. Sistema de controle e fornecimento de energia

9. Transportador de rolos, empilhador automático, transportador de corrente

E) Outras máquinas de conformação de rolos de purlin da NOVOTEK Feito

• Máquina de purlin C com empilhadeira: Saiba mais

Inclui um desbobinador hidráulico de 5T, uma máquina de achatamento, uma puncionadeira individual, uma perfiladeira principal para perfis em C com corte livre e uma empilhadeira automática para perfis em C. A velocidade máxima da máquina pode ser de 35 a 40 m/min, incluindo perfuração. O tamanho dos perfis pode ser personalizado e a espessura do aço pode ser de até 5 mm.

• Máquina de pré-perfuração e pré-corte para purlin CZ: Saiba mais

A Máquina de Perfilagem de Rolos de Purlin CZ Pré-cortada NTK-CZ-350AQ, Totalmente Automática e de Alta Resistência, adota um sistema de pré-corte e pré-puncionamento que dispensa o ajuste de fresas como a máquina de purlin CZ padrão, aumentando significativamente a operação da máquina. Graças ao seu design específico, ela pode produzir purlins CZU de até 350 mm e com espessura máxima de aço de 3 mm.

• Máquina de empilhamento de terças: Saiba mais

A Empilhadeira de Perfis CZ é usada para empilhar perfis CZU de 100-300 mm x 40-80 mm em quantidades e camadas predefinidas. A máquina pode ser personalizada de acordo com o tamanho do produto do cliente e também pode ser equipada com sua máquina perfiladeira de perfis CZ existente.

• Máquina de embalagem de tubos/purlin: Saiba mais

A Máquina Automática para Encapsulamento de Purlin e Tubos de Aço CZU foi projetada para embalar produtos de aço após o empilhamento. Assim como a empilhadeira de purlin mencionada acima, a embaladora também é o equipamento auxiliar subsequente da Máquina Automática para Encapsulamento de Purlin CZ NTK-CZ-300A.

F) Histórico de desenvolvimento da máquina de conformação de rolos de purlin NOVOTEK CZ

1. Estágio inicial (1998-2005)

Inicialmente, tratava-se de uma máquina de conformação de perfis em C e uma máquina de conformação de perfis em Z de tamanho único. O ajuste do tamanho final do produto era feito por espaçadores, o que demandava bastante tempo de operação a cada vez. O foco era a produção em pequena escala e com baixa precisão. As primeiras máquinas produziam principalmente perfis de aço simples em C e Z, amplamente utilizados em aplicações básicas de construção.

2. Avanço Semiautomático (2005-2010)

A primeira geração da máquina de conformação de perfis intercambiáveis CZ, NTK-CZ-300, foi inventada pela NOVOTEK, permitindo a produção de perfis C e Z em uma única máquina. A troca de perfis CZ é feita manualmente por meio da rotação de algumas estações de rolos, e o ajuste do tamanho das terças é acionado por motor elétrico e operado por botão. Trata-se de um avanço significativo na indústria de conformação de perfis e aumenta significativamente a capacidade e a eficácia do produto.

3. Integração totalmente automática (2010-2015)

Após esforços contínuos, a primeira máquina perfiladeira de perfis CZ totalmente automática NTK-CZ-300A da NOVOTEK é lançada. Ela adota um programa PLC para controlar a troca de perfis C e Z, bem como o ajuste de tamanho. Essa inovação aumentou o nível de automação da máquina perfiladeira de perfis CZ e reduziu o tempo de operação da máquina. Seu programa de controle automático permitiu um controle preciso, além da qualidade e exatidão do produto.

4. Fábrica Inteligente e de Informação (2015-atualmente)

As modernas máquinas de perfilagem de terças são equipadas com software avançado de controle de produção de arquivos CSV para conformação de rolos e recursos de monitoramento em tempo real. A incorporação de Wi-Fi e análise de big data facilita o gerenciamento automatizado e a otimização do processo de produção da máquina CZ. Juntamente com o sistema de corte de alta velocidade para terças, a empilhadeira automática para terças CZ e a envelopadora automática para terças , a NOVOTEK agora oferece uma solução completa para a fábrica inteligente de perfilagem de terças CUZ.

A Novotek tem como objetivo melhorar diversas capacidades de fabricação de máquinas de conformação de rolos, incluindo: perfil em U, perfil Sigma, perfil M, máquina de conformação de rolos de chapas de deck, máquina de conformação de rolos de chapas de telhado de alta velocidade para atender às demandas de produção personalizadas por meio de tecnologias inteligentes avançadas.