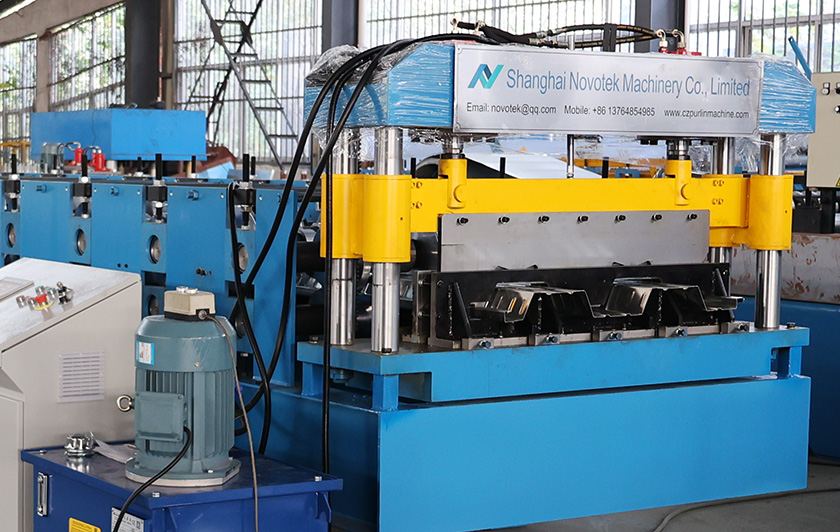

Deck Sheet Roll Forming Machine

The steel deck sheet roll forming machine, also called floor deck machine, is used to produce steel floor deck, which is widely used in steel buildings, large factories, and warehouses, etc.

The deck sheet plate meets the requirements of fast construction in main steel structure building, and can provide a stable operating platform in short time. In the stage of use, the steel floor deck plate is used as the tensile reinforcement of the concrete floor, which also improves the rigidity of the floor and saves the amount of steel and concrete.

The deck sheet plate surface embossing produces the maximum bonding force between the floor plate and the concrete, together with the stiffeners, the floor bearing plate system has a high strength.

Components of Steel Deck Sheet Machine

Hydraulic Uncoiler

1. Type: Hydraulic expanding, active uncoil

2. Load capacity: 5T

3. With or with out coil car

Main Roll Forming Machine of Floor Deck Making Machine

1.Roll stand: 26-34 stations, depends on the profile drawing

2. Main motor: 11Kw, it adopts cycloid cone pulley reducer, double chain transmission

3. Material of the roller: 45# forged steel, chromeplate

4. The roller processed by CNC machine with finish machining. The surface adopt finished polishing, the roughness is 0.05mm

5. Material of the main shaft: 45# forged steel with heat treatment, the hardness is HRB26-28

6. The diameter of the main shaft: Φ80mm

Main Roll Forming Machine of Floor Deck Making Machine

1. Adopt post cutting, automatic cut to length

2. Material of cutter: Cr12Mov, quenching, the hardness is HRC58-62

3. Cutting accuracy: 10m±2mm in length

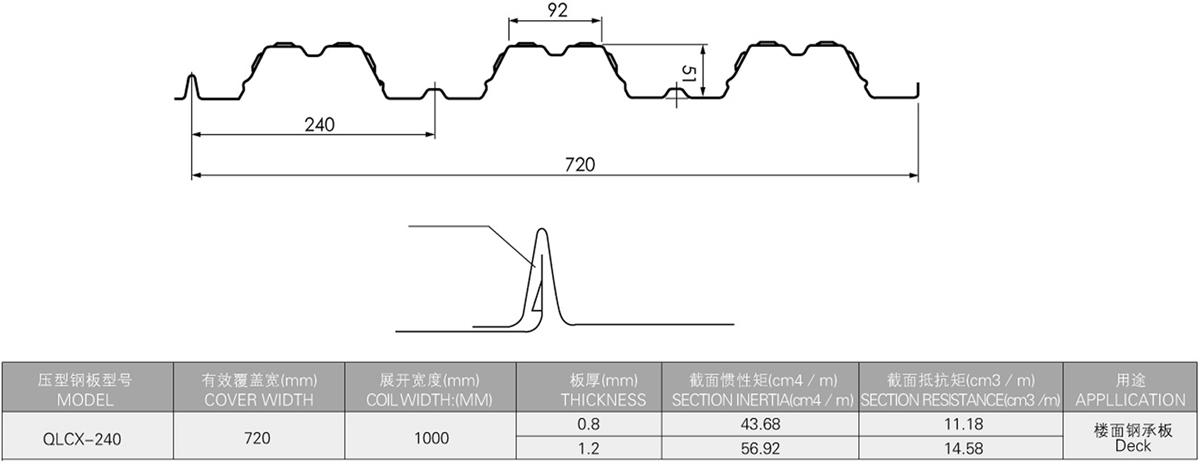

Typical Profile Drawing of Deck Sheet

사양

데크 시트 롤 성형기의 기술 사양

안건 | 매개변수 |

코일 두께(mm) | 1.0-1.5 |

롤 스탠드 | 30 |

주전원(Kw) | 30 |

메인 샤프트(mm) | Ø 100 |

커터 재료 | Cr12Mov |

절단 정확도 | 10±2mm |

유압 스테이션 전력(Kw) | 5.5 |

제어 시스템 | PLC |

주요 기계 치수(mm) | 12800 x 1500 x 800 |