Roof Sheet Roll Forming Machine (30m/min)

Novotek made high speed roof sheet roll forming machine is used to produce metal roof sheet, corrugated metal sheet, steel roof tile, etc. By using fly cut on the roll forming machine, our roof sheet machine speed can up to 30-40m/min actual running speed including cut.

They are popular because of their low cost, short building period; re-cycle use, and elegant appearance. They can be used as the roof of villas, luxury houses, theatres, exhibition centers.

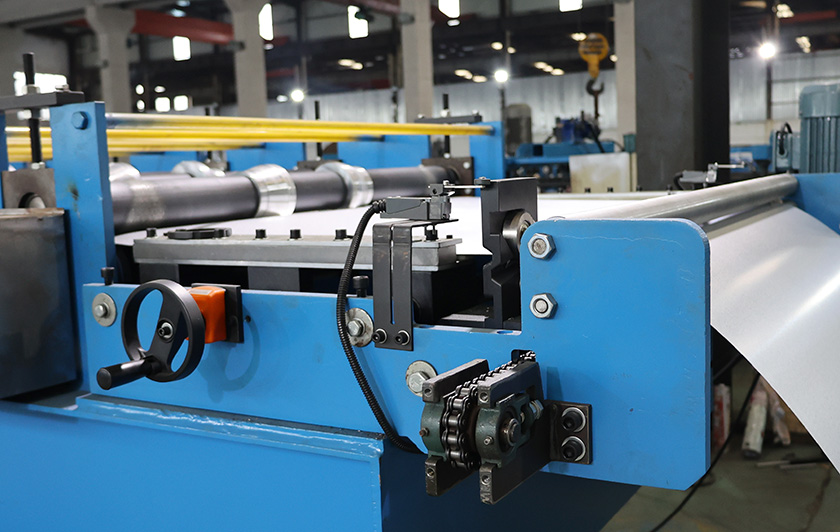

Main Machine of Roof Sheet Steel Machine

1. Roll stand: 16 stations, it includes leveling rollers, main forming rollers

2. Main motor power: 5.5KW, it adopts cycloid cone pulley reducer, chain or gearbox transmission

3. Material of the roller: 45# high grade steel, chromeplate

4. The roller processed by CNC machine with finish machining. The surface adopt finished polishing, the roughness is 0.05mm

5. Material of the main shaft: 45# forged steel with heat treatment

6. The diameter of the main shaft: Φ70mm

7. Machine frame: welding by 350 x 175mm H shape steel, by using carbon dioxide gas arc welding. The surface used shot blasting treatment.

Electric Control System of Roof Sheet Tile Machine

1. Control system: PLC (OMRON or MITSUBISHI brand)

2. Operation platform: touch screen and press button

3. Main motor: AC frequency conversion electric motor

4. Inverter (HOLIP brand), Touch panel (WEINVIEW or MITSUBISHI brand), low voltage electric parts (CHINT brand)

仕様

| アイテム | パラメーター |

| コイル厚(mm) | 0.3~0.7 |

| ロールスタンド | 16 |

| 主力 (Kw) | 5.5 |

| メインシャフト (mm) | φ70 |

| カッター材 | Cr12 |

| 切削精度 | 10±2mm |

| 油圧ステーション出力 (Kw) | 4 |

| 制御システム | シーケンサ |

| 本体寸法(mm) | 8500×1000×80 |