A) General Introduction

B) High Speed Purlin Roll Forming Machine Main Components

1. Hydraulic Uncoiler with Coil Car

2. Flattening Station

3. Punch Station

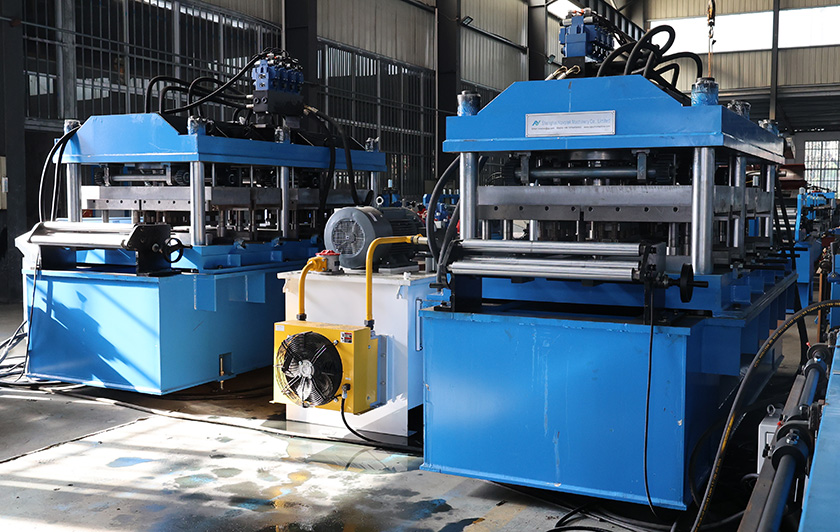

4. Main Roll Forming Line

5. Fly Cut

6. Power Supply & Control System

C) Roll Forming Machine Layout Flow

D) Detailed Description of Each Roll Forming Machine Systems

1. General

2. Raw Material

3. Hydraulic Uncoiler with Coil Car

4. Leveling Station

5. Punch Station

6. Main Roll Forming Machine

7. Fly Cut

8. Power Supply & Control System

9. Roller Conveyor, Auto-Stacker, Chain Conveyor

E) Other Purlin Roll Forming Machines that NOVOTEK Made

• C Purlin Machine with Stacking Machine: Learn More

It includes a 5T hydraulic uncoiler, flattening machine, individual punch machine, main C purlin roll forming machine with fly cut, and automatic C purlin stacking machine. The machine's maximum speed could be up to 35-40m/min including hole punching. The purlin size could be customized, and the steel thickness could be up to 5mm.

• Pre-Punch, Pre-Cut CZ Purlin Machine: Learn More

The Heavey Duty Fully Autoamtic NTK-CZ-350AQ Pre-cut CZ Purlin Roll Forming Machine adopts pre-cutting and pre-punching system which no need to adjust cutters as standard CZ purlin machine, and increase the machine operation a lot. By using a particular design, it can produce C Z U purlins up to 350mm and for maximum 3mm steel thickness.

• Purlin Stacking Machine: Learn More

The C Z Purlin Stacking Machine is used to stack 100-300mm x 40-80mm C Z U profiles as pre-set quantity and layers. The machine could be customized according to customer's product size, and also can be equipped with your existing C Z purlin roll forming machine.

• Purlin/Tube Packing Machine: Learn More

The automatic C Z U Purlin and Steel Tube Packing Machine is designed to wrapping the steel products after stacked. Same as the above purlin stacking machine, the wrapping machine is also the subsequent auxiliary equipment of the NTK-CZ-300A Automatic CZ Purlin Machine.

F) Development History of NOVOTEK CZ Purlin Roll Forming Machine

1. Early Stage (1998-2005)

Initially, it is a single C shape purlin roll forming machine and a single size Z shape roll forming machine. The final product size adjustment is by spacers which needs a lot of operation time each time. They were focusing on small-scale production with low precision. Early machines primarily produced simple C and Z-shaped steel profiles, widely used in basic construction applications.

2. Semi-Automatic Advancement (2005-2010)

The first generation CZ interchangeable roll forming machine NTK-CZ-300 was first invented by NOVOTEK which both C channel and Z channel can be produced on one machine. The CZ profile interchange is by manually rotate some roller stations, and the purlin size adjustment is driven by electrical motor and operated through button. It is a significant movement of purlin roll forming industry and it increases the product capacity and efficacy a lot.

3. Fully Automatic Integration (2010-2015)

After continuous efforts, NOVOTEK first NTK-CZ-300A fully automatic CZ purlin roll forming machine is launched. It adopts PLC program to control the C & Z purlin interchange, as well as the size adjustment. This innovation increased the CZ purlin roll forming machine automation level and reduced the CZ machine operation time. Its automatic control program enabled precision control and the product quality and accuracy.

4. Smart and Information Factory (2015-now)

Modern purlin machines are equipped with advanced roll forming CSV file production control software and real-time monitoring capabilities. The incorporation of WIFI and big data analytics facilitates automated management and optimization of the C Z machine production process. Together high speed purlin fly cutting system, automatic CZ purlin stacking machine, automatic purlin wrapping machine, NOVOTEK now providing an entire solution for the smart C U Z purlin roll forming factory.

Novotek is aiming to improve various roll forming machine manufacturing capabilities including: U purlin, Sigma Profile, M Profile, Deck Sheet Roll Forming Machine, High Speed Roof Sheet Roll Forming Machine to meet customized production demands through advanced smart technologies.