Guardrail Roll Forming Machine

High speed guardrail roll forming machine is used to produce guardrail, which is the most-used steel structures in highway construction. There are 2 different models, three waves or five waves shape according to different standard.

In Novotek we produce guardrail roll forming machine in different types: fixed cut type, fly punch and fly cut type, and separated punch and fly cut type, with different machine running speed.

Also it can include a special automatic stacking machine.

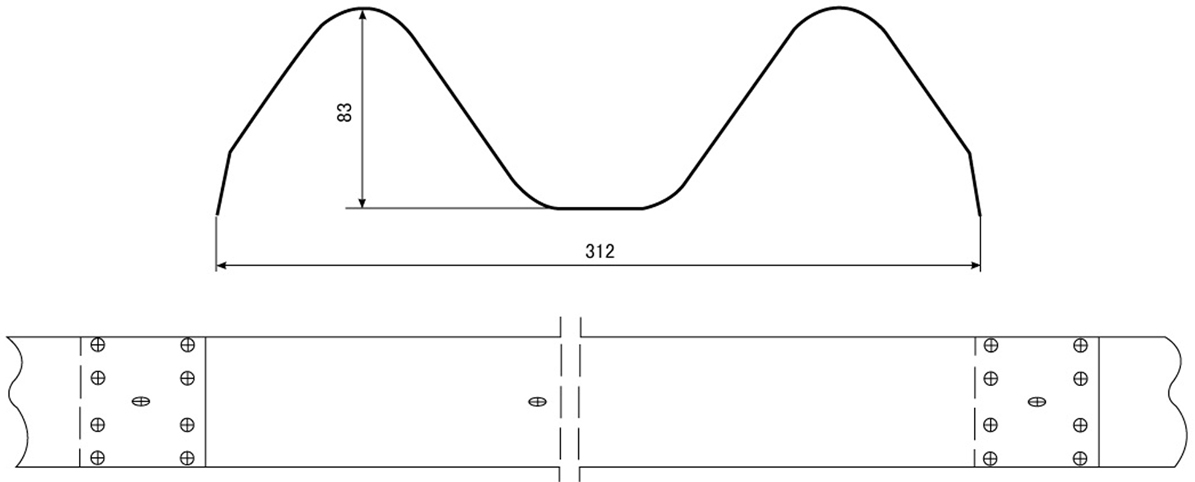

Typical Guardrail Shape Profile Drawing

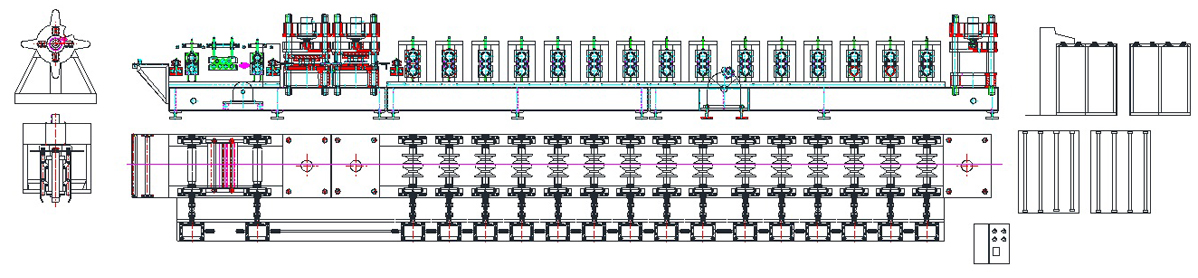

Guardrail Machine Layout

High speed guardrail roll forming machine is a kind of tile roll forming machine. It comprises a frame, an upright arm, a head, an upper pressing die, a lower pressing die, and a power device that drives the upper pressing die. The power device comprises a hydraulic pump, a motor that drives the hydraulic pump to work, a hydraulic cylinder driven by the hydraulic pump, the piston rod of the hydraulic cylinder is fixedly connected with the upper pressure die, the hydraulic pipe road is also provided with a relief valve and a manual reversing valve, the hydraulic cylinder rod - free chamber of the inlet pipe is also provided with a filling valve.

High-speed guardrail roll forming machine is a hydraulic press used to shape and press the rough tile blank after being extruded and cut by vacuum spiral extruder when wet glazed tile is produced. The products produced by high-speed guardrail machine have the characteristics of light weight and heavy bearing, and are widely used in the field of multi-high-rise steel structure construction.

The use of high speed guardrail roll forming machine makes the management level of the highway improve, reduce the occurrence of traffic accidents, to a greater extent to meet the smooth highway, highway to achieve high speed, high management level.

Specification

| Item | Parameters |

| Coil thickness (mm) | 3-4 |

| Roll stand | 22 |

| Main power (Kw) | 30 |

| Transmission system | Gearbox |

| Roller material | Gcr15 |

| Main shaft (mm) | Ø 110 |

| Cutter material | Cr12Mov |

| Cutting accuracy | 10±2mm |

| Hydraulic station power (Kw) | 11 |

| Control system | PLC |

| Main machine dimension (mm) | 15600x 1000 x 800 |