Glazed Tile Roll Forming Machine

Glazed tile roll forming machine can produce different shapes of glazed tile roof sheets in various thickness and colors. Compared with traditional ceramic tiles, it is much popular because of their economic cost, light weight, short building period; re-cycle use, and elegant appearance.

It can be used as the roof of villas, luxury houses, theaters, exhibition centers, etc.

Main Machine of Steel Glazed Roof Tile Machine

Roll stand: 16 stations, it includes leveling rollers, main forming rollers

Main motor power: 5.5KW, it adopts cycloid cone pulley reducer, chain transmission

Material of the roller: 45# high grade steel, chromeplate

The roller processed by CNC machine with finish machining. The surface adopt finished polishing, the roughness is 0.05mm

Material of the main shaft: 45# forged steel with heat treatment

The diameter of the main shaft: Φ70mm

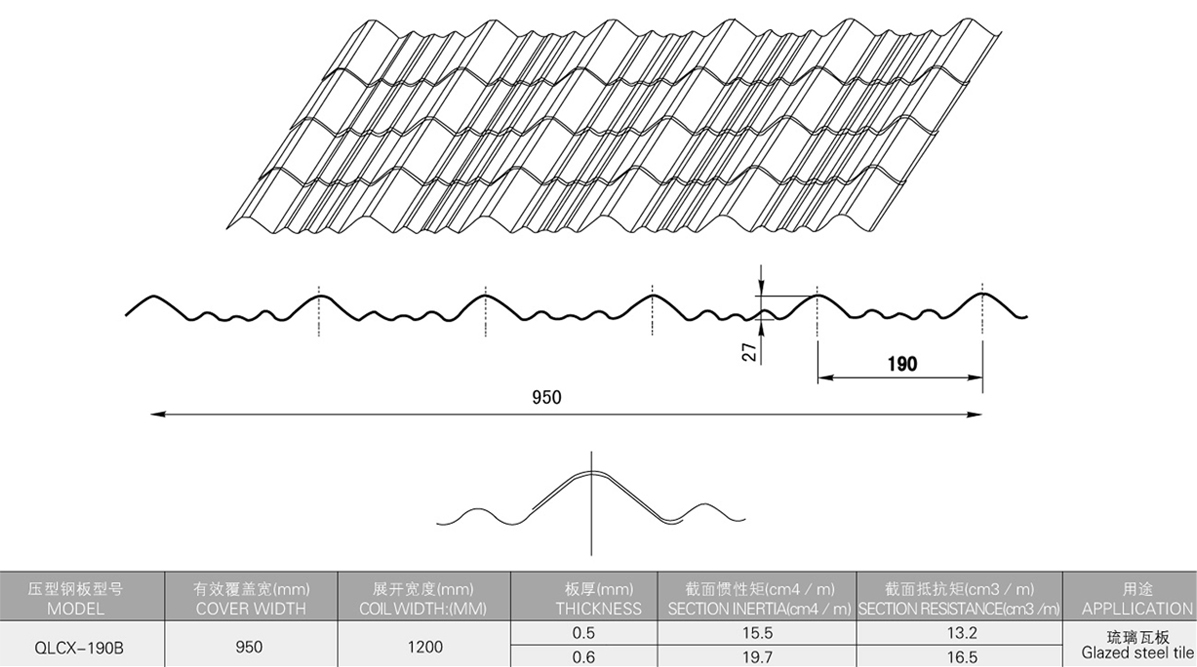

Typical Shape Profile of Glazed Tile

Specification

Technical Parameters of Glazed Roof Tile Roll Forming Machine

| Item | Parameters |

| Coil thickness (mm) | 0.4-0.6 |

| Roll stand | 16 |

| Main power (Kw) | 5.5 |

| Main shaft (mm) | Ø70 |

| Cutter material | Cr12 |

| Cutting accuracy | 10±2mm |

| Hydraulic station power (Kw) | 4 |

| Control system | PLC |

| Main machine dimension (mm) | 9600 x 1600 x 800 |