Fully Automatic CZ Purlin Roll Forming Machine

The NOVOTEK Fully Automatic #CZ Purlin Roll Forming Machine 2024# is designed to produce C U Z profiles in various sizes and thicknesses. This machine is also known as the Fast Change C/Z Purlin Interchangeable Making Machine or C & Z Lipped Channel Roll Forming Machine. This advanced equipment offers automation for efficient and precise production.

As the largest and leading manufacturer of CZ Purlin Machines in China, NOVOTEK has delivered approximately 300 sets annually over the past ten years. Also, we are the only factory in China that supplies fully automatic types, ensuring the highest quality and innovation in the industry.

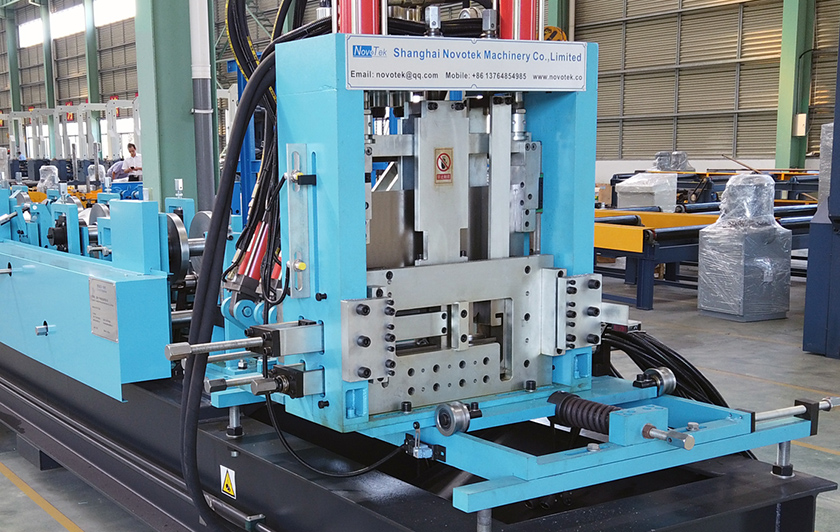

Main Components of the NTK-CZ-300A Purlin Machine

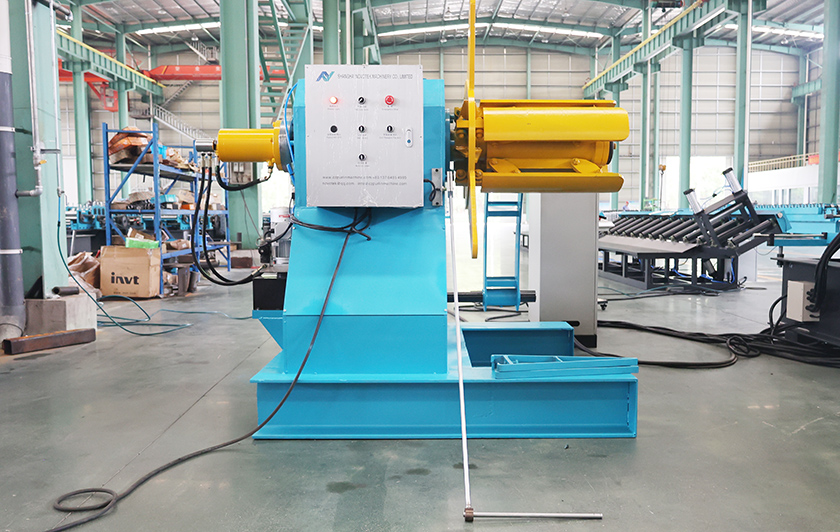

1) Uncoiler:

• Type: Mechanical Uncoiler, or Hydraulic Uncoiler.

• Load Capacity: 7T

• Coil Inner Diameter: 480-580mm

• Expanding Type: Hydraulic expanding

• Decoil Type: Motorized active decoil

2) Main CZ Roll Forming Machine:

• Flattening Station: Adopts 7 rollers solid shaft plus extra pinch rollers to flatten the steel coils.

• Roller Material: High grade wear-resistant material with heat treatment, polishing, and galvanizing.

• Purlin Machine Main Drive: Hydraulic motor or servo motor drive.

• Machine Main Shaft: the material is 40Cr, with heat treatment, polishing and galvanizing.

• CZ Interchange: Automatic PLC controlled with touch panel settings.

• Purlin Size Adjustment: Continuously adjustable via PLC control and touch panel settings.

3) Hydraulic Punching & Universal Cutting System:

• Punching Unit: 3 sets + 2 sets.

• Hole Locations: Product web side, flange side

• Hole Type: Round hole, slot holes

• Universal Cutters: One cutter suitable for all C and Z purlin sizes.

• Machine Control: Cutting length, pieces, and punching are automatically controlled by PLC.

3) Other Optional Systems:

• Inkjet Printer: Used to print company name, logo, and code, etc on purlin flange.

• Pre-shearer: Can be used to change steel coils in the middle of machine production.

• Pre-punch: To punch holes and slots before forming on flat stee sheet.

• Auto-stacker: Automatic stacking the C and Z purlins.

• Extra punch sets: More punch sets are available in order to increase the machine punch capacity.

Key Advantages of Fully Automatic CZ Purlin Interchangeable Machine (NTK-CZ-300A)

a) Machine Automation High Level:

• Fully Automatic CZ Interchange: Fast change between C purlin and Z purlin, the interchange is automatic controlled by program settings.

• Fully Automatic Purlin Size Adjustment: Size changes also are automated and controlled via the machine control program.

b) Wide Range for Steels and Purlins:

• Raw Material Types: Galvanized steel, black steel.

• Thickness Range: 1.5-3.0mm. (Also we have NTK-CZ-400A CZ Purlin Machine for 2.0-4.0mm thickness steel)

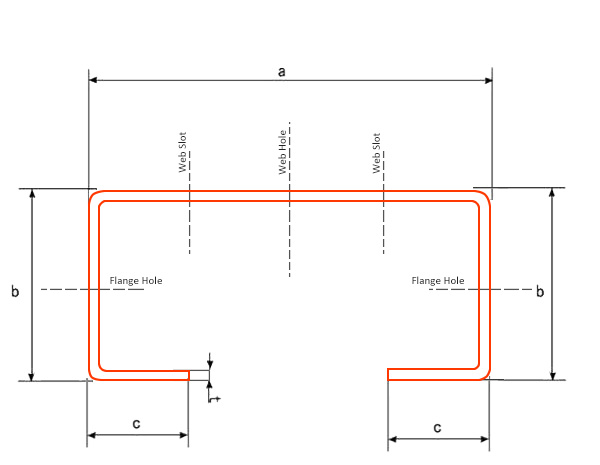

• Product Dimensions:

• C Purlin Size: a80-300mm x b40-80mm x c10-20mm x t1.5-3.0mm

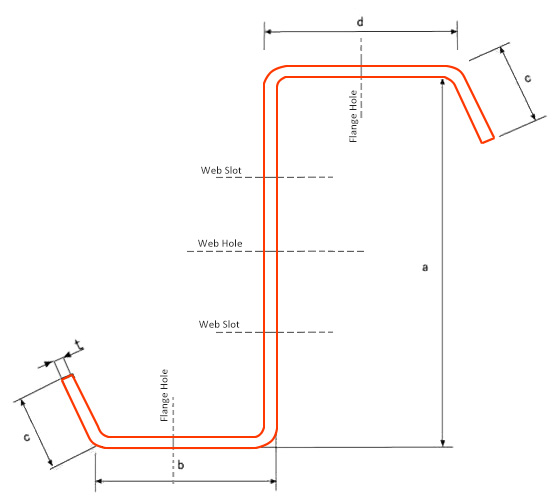

• Z Purlin Width: a120-300mm x b40-80mm x c10-20mm x t1.5-3.0mm

• Can Upgrade to NTK-CZ-320A Automatic CZ Machine (product size: c80-320mm x b40-90mm x c10-25mm x t1.5-3.2mm)

c) Other Advantages:

• Universal Cutter: One cutter assembly suitable all C, Z, and U purlin sizes.

• Fast Change: Quick change between various C Z purlin types within minutes.

• Adjustability: Product web, flange, and lip dimensions are adjustable in millimeters.

• Through Shaft Design: Reduces issues of uneven heights due to broken machine main shafts.

• High-Strength Construction: The main roll forming machine structure is made from cold-pressed high-strength steel plate with uniform wall thickness, high compressive strength.

• High Accuracy: The final product has high accuracy, offset of length and purlin punch position can be adjusted easily.

Other Purlin Roll Forming Machines that NOVOTEK Made

• C Purlin Machine with Stacking Machine: Learn More

It includes a 5T hydraulic uncoiler, flattening machine, individual punch machine, main C purlin roll forming machine with fly cut, and automatic C purlin stacking machine. The machine's maximum speed could be up to 35-40m/min including hole punching. The purlin size could be customized, and the steel thickness could be up to 5mm.

• Pre-Punch, Pre-Cut CZ Purlin Machine: Learn More

The Heavey Duty Fully Autoamtic NTK-CZ-350AQ Pre-cut CZ Purlin Roll Forming Machine adopts pre-cutting and pre-punching system which no need to adjust cutters as standard CZ purlin machine, and increase the machine operation a lot. By using a particular design, it can produce C Z U purlins up to 350mm and for maximum 3mm steel thickness.

• Purlin Stacking Machine: Learn More

The C Z Purlin Stacking Machine is used to stack 100-300mm x 40-80mm C Z U profiles as pre-set quantity and layers. The machine could be customized according to customer's product size, and also can be equipped with your existing C Z purlin roll forming machine.

• Purlin/Tube Packing Machine: Learn More

The automatic C Z U Purlin and Steel Tube Packing Machine is designed to wrapping the steel products after stacked. Same as the above purlin stacking machine, the wrapping machine is also the subsequent auxiliary equipment of the NTK-CZ-300A Automatic CZ Purlin Machine.

Development History of NOVOTEK CZ Purlin Roll Forming Machine

1. Early Stage (1998-2005)

Initially, it is a single C shape purlin roll forming machine and a single size Z shape roll forming machine. The final product size adjustment is by spacers which needs a lot of operation time each time. They were focusing on small-scale production with low precision. Early machines primarily produced simple C and Z-shaped steel profiles, widely used in basic construction applications.

2. Semi-Automatic Advancement (2005-2010)

The first generation CZ interchangeable roll forming machine NTK-CZ-300 was first invented by NOVOTEK which both C channel and Z channel can be produced on one machine. The CZ profile interchange is by manually rotate some roller stations, and the purlin size adjustment is driven by electrical motor and operated through button. It is a significant movement of purlin roll forming industry and it increases the product capacity and efficacy a lot.

3. Fully Automatic Integration (2010-2015)

After continuous efforts, NOVOTEK first NTK-CZ-300A fully automatic CZ purlin roll forming machine is launched. It adopts PLC program to control the C & Z purlin interchange, as well as the size adjustment. This innovation increased the CZ purlin roll forming machine automation level and reduced the CZ machine operation time. Its automatic control program enabled precision control and the product quality and accuracy.

4. Smart and Information Factory (2015-now)

Modern purlin machines are equipped with advanced roll forming CSV file production control software and real-time monitoring capabilities. The incorporation of WIFI and big data analytics facilitates automated management and optimization of the C Z machine production process. Together high speed purlin fly cutting system, automatic CZ purlin stacking machine, automatic purlin wrapping machine, NOVOTEK now providing an entire solution for the smart C U Z purlin roll forming factory.

Novotek is aiming to improve various roll forming machine manufacturing capabilities including: U purlin, Sigma Profile, M Profile, Deck Sheet Roll Forming Machine, High Speed Roof Sheet Roll Forming Machine to meet customized production demands through advanced smart technologies.

Specification

Technical Specification of NTK-CZ-300A Purlin Machine

| Raw Material | Type | Galvanized Sheet, Black Sheet |

| Thickness | 1.5-3.0mm (1.2-3.2mm) | |

| C Purlin Size | Web x Flange x Lip | 80-300/ 30-80/ 10-20 |

| Z Purlin Size | Web x Flange x Lip | 120-300/ 30-80/ 10-20 |

Performance |

Speed | Max. 30m/min (by servo motor driven) |

| C & Z Interchange | PLC Control, Fully Automatic | |

| Size Change | PLC Control, Fully Automatic | |

| Uncoiler | Type | Mechanical or Hydraulic |

| Capacity | 6 T | |

Main Machine |

Main Roller Station | 18 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

Punching & Cutting |

Punching Location | Web + Flange |

| Punching Unit | 3 Sets + 2 Sets | |

| Cutter Type | Universal Cutter |