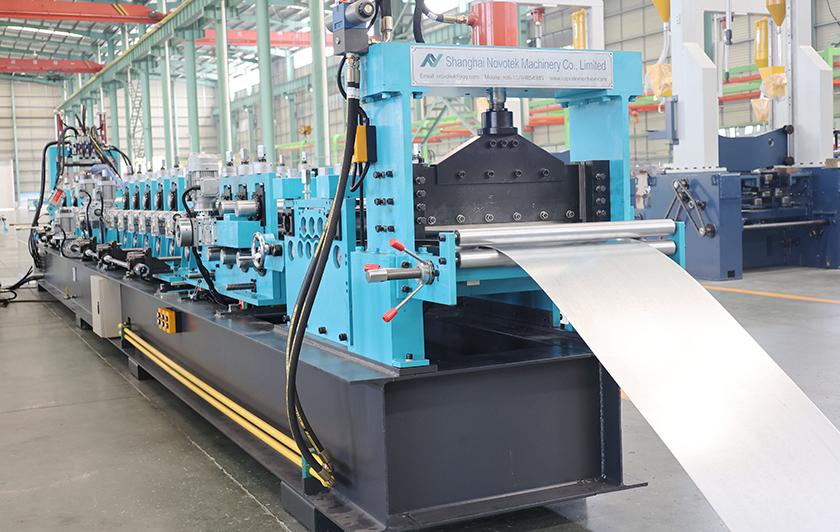

NOVOTEK 2024 Fully Automatic CZ Purlin Roll Forming Machine NTK-CZ-320A

The NOVOTEK 2024 latest Fully Automatic CZ Purlin Roll Forming Machine, also known as the Fast Change C/Z Purlin Interchangeable Making Machine or C U & Z Lipped Channel Roll Forming Machine, is designed to produce both C U and Z profiles in various sizes and thicknesses. This machine can punch holes on either the purlin web or flange side, providing flexibility and precision in production.

Key Features of NTK-CZ-320A Fully Automatic CZ Machine

Automated Interchangeability:

-

CZ Channel Interchange Unit: Enables seamless switching between C and Z purlin production, controlled by PLC and adjustable via a touch panel.

-

Size Change Unit: Allows continuous adjustment of purlin sizes, controlled by PLC and set through the touch panel for ease of operation.

High-Quality Components:

-

Uncoiler: Available in mechanical or hydraulic types with a load capacity of 6 tons, supporting substantial raw material weight.

-

Purlin Machine: Made with GCr15 steel rollers, treated with heat, polishing, and galvanizing for enhanced durability. The main motor is available in hydraulic or servo motor drive options.

Hydraulic Punching & Universal Cutting System:

-

Punching Unit: Equipped with 3+2 sets for comprehensive punching capabilities.

-

Universal Cutters: Adaptable for all sizes of C and Z purlins, ensuring precise and clean cuts.

-

Control System: Cutting lengths, number of pieces, and punching operations managed via a PLC system for high precision and efficiency.

Main Technical Specifications

-

Raw Material: Suitable for galvanized sheet and black sheet, with a thickness range of 1.5-3.2mm.

-

Product Dimensions:

-

C U Purlin Width: 80-320mm

-

Z Purlin Width: 120-300mm

-

Larger sizes available with the NTK-CZ-400A model

-

-

Machine Speed: Maximum speed of 30 meters per minute, driven by a servo motor for precise control.

Production Capacity and Market Leadership

- Annual Production: Approximately 300 sets of Purlin Machines delivered each year over the past five years.

- Market Position: Recognized as the leading and largest manufacturer of C&Z Purlin Machines in China and the exclusive supplier of fully automatic purlin machines in the Chinese market.

NOVOTEK’s NTK-CZ-320A model represents the pinnacle of innovation in purlin roll forming technology, catering to diverse industrial needs with advanced automation, versatility, and robust design. Ideal for constructing frames, supports, and other structural applications, this machine ensures high performance and reliable output.

spécification

Technical Specification of NTK-CZ-320A Purlin Machine

| Raw Material | Type | Galvanized Sheet, Black Sheet |

| Thickness | 1.5-3.0mm (1.2-3.2mm) | |

| C Purlin Size | Web x Flange x Lip | 80-300/ 30-80/ 10-20 |

| Z Purlin Size | Web x Flange x Lip | 120-300/ 30-80/ 10-20 |

Performance |

Speed | Max. 30m/min (by servo motor driven) |

| C & Z Interchange | PLC Control, Fully Automatic | |

| Size Change | PLC Control, Fully Automatic | |

| Uncoiler | Type | Mechanical or Hydraulic |

| Capacity | 6 T | |

Main Machine |

Main Roller Station | 18 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

Punching & Cutting |

Punching Location | Web + Flange |

| Punching Unit | 3 Sets + 2 Sets | |

| Cutter Type | Universal Cutter |