Descripción general de la máquina formadora de correas en Z

La máquina formadora de rollos de correas en forma de Z, también conocida como formadora de rollos de correas en forma de Z de acero galvanizado, se utiliza para la producción de acero tipo Z. El acero de correas en forma de Z tiene buenas propiedades de resistencia a la flexión, buena rectitud y también se puede perforar y cortar en línea.

Diagrama de flujo de la máquina de correas Z

Desenrollador → Precortador → Aplanado y guiado → Máquina formadora de rollos principal → Impresora de inyección de tinta → Punzonadora hidráulica → Postcortador → Mesa de salida

Componentes de la máquina perfiladora de correas Z

Desenrollador hidráulico

1) Tipo de expansión: Expansión hidráulica

2) Tipo de desbobinado: desbobinado activo motorizado

Sistema de aplanamiento y guía

1) Sistema de aplanamiento: 3 ejes superiores y 4 inferiores sólidos, más 4 ejes de presión adicionales.

2) Sistema de guía: incluye eje guía y rodillos guía, su ancho es ajustable para adaptarse a varias tiras de acero.

3) Material del eje: mecanizado CNC, temple con tratamiento térmico de revenido, torneado de acabado, pulido y cromado.

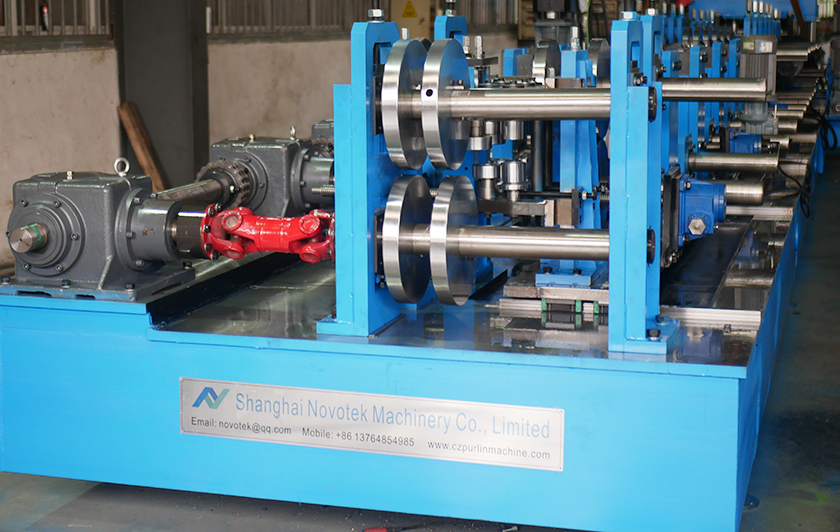

Máquina formadora de rollos principal

1) Puesto de control: 21 estaciones principales

2) Tipo de transmisión: Cadena + engranaje/piñón

3) Base de la máquina: Soldada con placa H500, con granallado y tratamiento térmico.

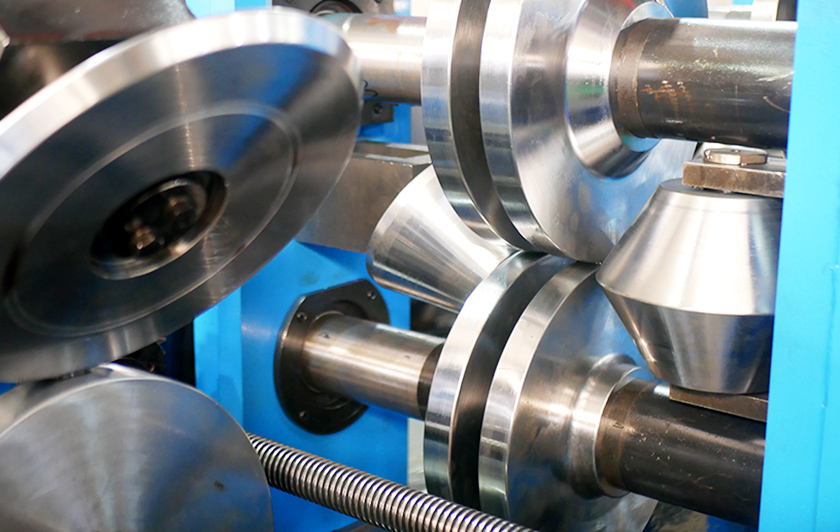

4) Material del rodillo: GCR15, mecanizado CNC con tratamiento térmico, torneado de acabado, pulido y cromado. HRC 58-60

5) Eje principal: SAE 5140, mecanizado CNC, temple con tratamiento térmico de revenido, torneado de acabado, pulido y cromado.

6) Motor principal: servomotor principal.

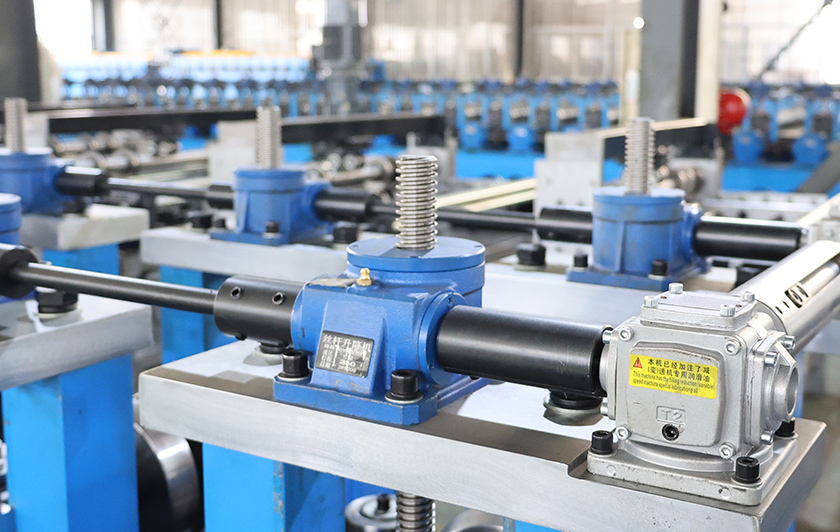

7) Cambio de tamaño: totalmente automático mediante PLC

8) Unidad de enderezamiento de correas: 10 rodillos, dos unidades de enderezamiento axial especiales más 4 unidades de enderezamiento axial de rodillos para garantizar que la correa no se curve, arquee, barra ni tuerza.

Punzonado hidráulico

1) Tipo: Adopta post-punción, punzón automático para configurar los parámetros.

2) Cilindro de perforación: 3 juegos

3) Matriz de punzonado: según los requisitos del cliente.

Post-cortador

1) Tipo: Adopta corte posterior, corte automático a longitud, cantidad, etc.

2) Material de corte: SAE-AISI D3, temple.

Sistema de suministro de energía y control

1) Armario de control: 1 juego. Con interruptor de parada de emergencia.

2) Mango de control: 1 juego, para control de avance durante la prueba y producción de la máquina.

3) Plataforma de operación: HMI y botón, con pantalla en idioma inglés.

Tabla de salida

1) Tipo: Dos juegos, 3 metros cada uno, tipo rodillo libre.

Tamaño de correa Z fabricada por la máquina perfiladora Novotek

Banda: 120-300 mm x Brida: 40-80 x Labio: 10-20 mm (NTK-CZ-300A)

Banda: 120-400 x Brida: 50-100 x Labio: 10-25 mm (NTK-CZ-400A)

También están disponibles otras máquinas formadoras de correas Z personalizadas.

Uniones de correas en Z para techo

1. Las correas Z generalmente están galvanizadas y se instalan en el lado alto a lo largo de la pendiente longitudinal.

2. Las correas Z se conectan a las vigas de acero con pernos de clase C ordinarios a través de placas de soporte de correas, las placas de soporte de correas y las vigas de acero se sueldan en un todo en la fábrica y se recubren con la imprimación y pintura intermedia correspondientes.

3. Las correas Z se conectan a cabezas grandes y pequeñas para distinguirlas, la profundización y el procesamiento deben ser consistentes con la secuencia de construcción del sitio, y el tamaño de la cabeza está conectado.

4. Las correas Z se pueden reducir aumentando el número de perforaciones para facilitar la instalación en obra (las correas de pared son las mismas).

Diferencia entre correa C y correa Z

1. Según la forma de la correa: el ángulo de la correa de acero tipo Z y el de la correa de acero tipo C no es el mismo: el de la correa tipo C es de 90 grados y el de la correa tipo Z es inferior a 90 grados, aproximadamente entre 60 y 75 grados. Por lo tanto, si se requieren correas en un techo con cierta pendiente, es necesario considerar el ángulo de la correa y su fuerza de apoyo, para que la correa tipo Z pueda aprovechar al máximo su capacidad de flexión.

2. Si se desea convertir la correa en elementos continuos, es mejor usar la correa Z en comparación con la correa C, ya que la superposición de la correa de acero Z es más conveniente.

3. Desde el punto de flexión: si la pendiente del techo es pequeña, el módulo de flexión de la correa metálica Z es ligeramente mayor que el de la correa C. Si la pendiente del techo es grande, la tasa de utilización del módulo de la correa Z simétrica en dirección vertical es muy alta, por lo que es más adecuada para techos con grandes pendientes.

4. Las propiedades mecánicas de las dos correas son muy diferentes: la sección en Z se puede conectar mediante una junta traslapada fiable, lo que se puede calcular según la viga continua. Por lo tanto, para aberturas de puertas y ventanas y otras necesidades especiales de procesamiento de nodos, se recomienda utilizar correas de sección en Z. Las correas de muro y de vivienda con poca pendiente pueden utilizar correas en C. En las correas de vivienda con gran pendiente, se deben considerar correas de acero en forma de Z, de modo que la fuerza resultante de la carga del techo pase por el centro de la sección de la correa en forma de Z.

Otras máquinas perfiladoras de correas fabricadas por NOVOTEK

• Máquina de correas C con apiladora: Más información

Incluye un desenrollador hidráulico de 5 toneladas, una aplanadora, una punzadora individual, una perfiladora de correas C principales con corte en abanico y una apiladora automática de correas C. La velocidad máxima de la máquina puede alcanzar los 35-40 m/min, incluyendo la perforación de agujeros. El tamaño de las correas se puede personalizar y el espesor del acero puede alcanzar hasta 5 mm.

• Máquina para correas CZ precortadas y perforadas: Más información

La perfiladora de correas CZ precortadas NTK-CZ-350AQ, totalmente automática y de alta resistencia, incorpora un sistema de precorte y prepunzonado que elimina la necesidad de ajustar las cuchillas como las máquinas estándar para correas CZ, lo que optimiza considerablemente su funcionamiento. Gracias a su diseño específico, puede producir correas CZU de hasta 350 mm con un espesor de acero máximo de 3 mm.

• Máquina apiladora de correas: Más información

La apiladora de correas CZ permite apilar perfiles CZU de 100-300 mm x 40-80 mm en cantidades y capas predefinidas. La máquina se puede personalizar según el tamaño del producto del cliente y también puede equiparse con su perfiladora de correas CZ existente.

• Máquina empacadora de correas/tubos: Más información

La máquina empacadora automática de correas y tubos de acero CZU está diseñada para envolver productos de acero tras su apilado. Al igual que la apiladora de correas mencionada anteriormente, la máquina empacadora es también el equipo auxiliar de la máquina empacadora automática de correas CZ NTK-CZ-300A.

Historial de desarrollo de la máquina perfiladora de correas NOVOTEK CZ

1. Etapa temprana (1998-2005)

Inicialmente, se trataba de una perfiladora de correas en forma de C y una perfiladora en forma de Z. El ajuste del tamaño del producto final se realizaba mediante espaciadores, lo que requería un tiempo de operación considerable. Se centraban en la producción a pequeña escala con baja precisión. Las primeras máquinas producían principalmente perfiles de acero simples en forma de C y Z, ampliamente utilizados en aplicaciones de construcción básica.

2. Avance semiautomático (2005-2010)

La perfiladora intercambiable CZ de primera generación, NTK-CZ-300, fue inventada por NOVOTEK y permite producir perfiles C y Z en una sola máquina. El intercambio de perfiles CZ se realiza mediante la rotación manual de varias estaciones de rodillos, y el ajuste del tamaño de las correas se acciona mediante un motor eléctrico y un botón. Este avance significativo en la industria del perfilado de correas aumenta considerablemente la capacidad y la eficiencia del producto.

3. Integración totalmente automática (2010-2015)

Tras continuos esfuerzos, NOVOTEK lanzó al mercado la primera máquina perfiladora de correas CZ totalmente automática, la NTK-CZ-300A . Incorpora un programa PLC para controlar el intercambio de correas C y Z, así como el ajuste de tamaño. Esta innovación incrementó el nivel de automatización de la perfiladora de correas CZ y redujo el tiempo de operación de la máquina. Su programa de control automático permitió un control preciso y la calidad y exactitud del producto.

4. Fábrica inteligente y de información (2015-actualidad)

Las máquinas modernas de correas están equipadas con un avanzado software de control de producción de archivos CSV de perfilado y funciones de monitorización en tiempo real. La incorporación de wifi y análisis de big data facilita la gestión automatizada y la optimización del proceso de producción de las máquinas CZ. Junto con el sistema de corte de correas de alta velocidad, la apiladora automática de correas CZ y la envolvedora automática de correas , NOVOTEK ofrece ahora una solución integral para la fábrica inteligente de perfilado de correas CUZ.

Novotek tiene como objetivo mejorar varias capacidades de fabricación de máquinas formadoras de rollos, incluidas: máquinas formadoras de rollos de correas en U, perfiles Sigma, perfiles M, máquinas formadoras de rollos de láminas para cubiertas y máquinas formadoras de rollos de láminas para techos de alta velocidad para satisfacer las demandas de producción personalizadas a través de tecnologías inteligentes avanzadas.